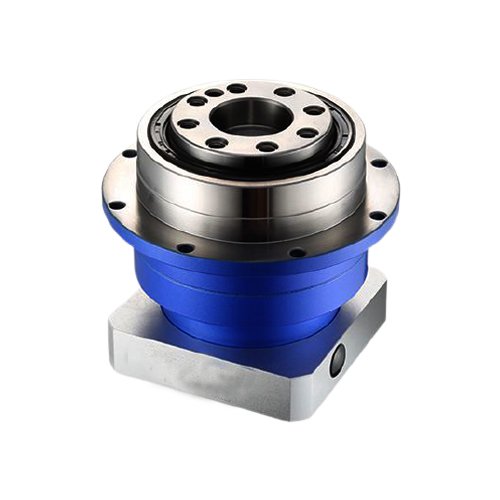

Each servo planetary gearbox has a rated input speed and a number of planetary gears. As only one set of planetary gears cannot meet a large transmission ratio, then sometimes two or three sets of such gears are required to meet the requirements of the user. That is to say, the larger the reduction ratio is, the more numbers stages will be needed, and the lower the efficiency will be.

Well, how to check the backlash of MKD low backlash planetary gearbox ?

Fix the output end and rotate the input end in the direction of clockwise and counterclockwise, which will generate rated torque about +-2% of torque, and there will be a slight angular displacement on the input end, which is called backlash. The unit is “minute”, which is one-sixtieth of a degree. It is also known as return clearance. The nominated input speed of the servo planetary gearbox can reach up to 18000 rpm (depending on the size of the gearbox itself. The larger the reducer is, the smaller the rated input speed will be). The output torque of the industrial servo planetary gearbox is normally not more than 2000Nm, and the customized gearbox with super-torque can achieve an output torque more than 10000Nm. The working temperature range is generally from -25°C to 100°C. The operating temperature can be changed by changing the grease.

Therefore, the efficiency of the servo planetary gear box is related to the number of stages of the reducer.