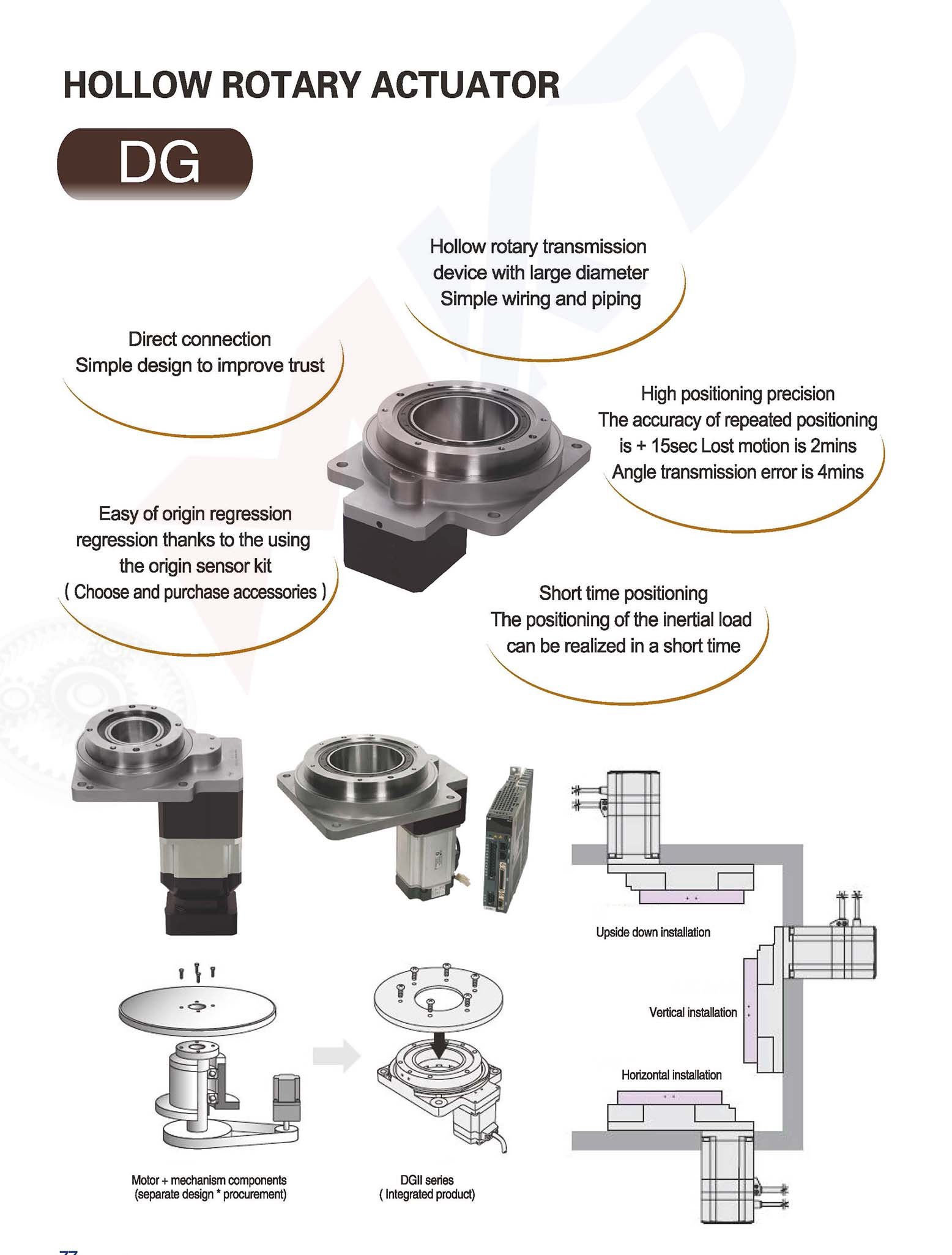

DG is a kind of series product that integrates high rigidity hollow rotary actuator and a closed-loop stepper motor. It features of easy use of stepper motor and meantime large inertia loads can be positioned with a high degree of accuracy.

DG Series hollow rotating actuator uses high-precision gear structure and radial bearings to improve the torque and rigidity, which makes the load more stable. Besides, the servo motor or the stepping motor can be arbitrarily cut to meet the number of bits that the cam indexer can not control, and the positioning accuracy can be comparable to the direct drive. The hollow rotating actuator can realize positioning of inertial load in a short time.

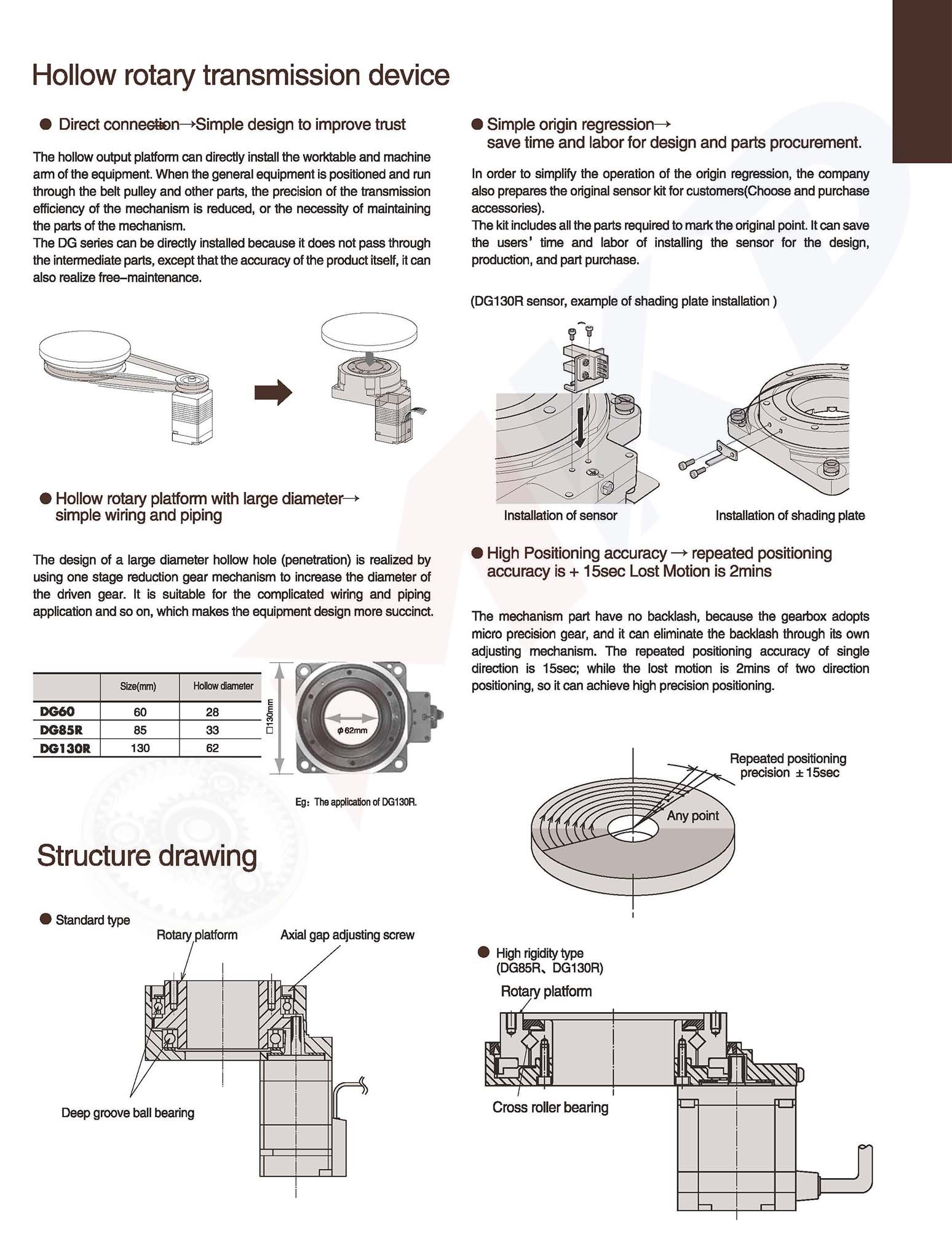

The work table, machine arm or other load can be directly installed on the hollow rotary output stage. Therefore, the fastening components such as the coupling, the power transmission components such as the pulley and maintenance are all not needed.

High precision positioning without backlash allows high accuracy positioning within 2′ (0.033 degree) idling motion.

The hollow large diameter structure output stage has a hollow structure with a diameter of 28 mm. Therefore, the design of your device can be simplified and the installation space can be saved by crossing the hollow parts through pipes and wires.

Quick response and high reliability. The stepper motor used by the DG series hollow rotary actuator does not allow positioning errors even when the load suddenly changes. The rotating speed and the volume are monitored during operation, and the response delay will be corrected and the operation of DG actuator will be continued within the maximum operating torque range when the possibility of step losing is detected as a result of overload.

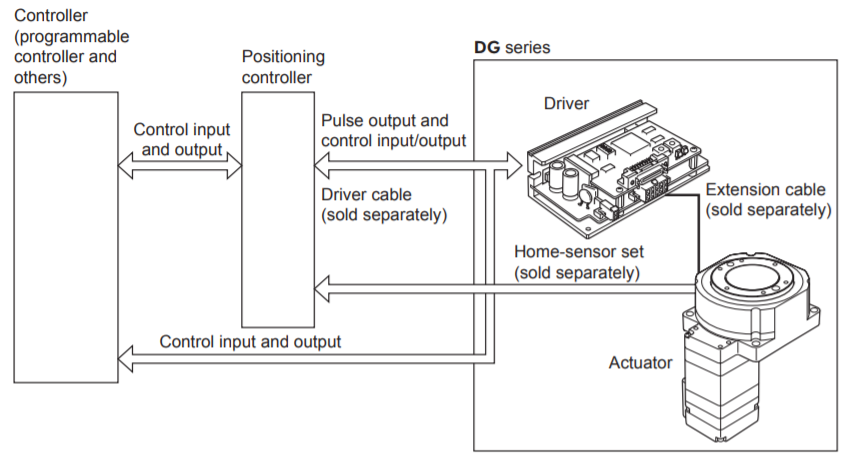

Note: The operation of DG Series hollow rotary reducer needs the controller with pulse output function to operate.

Application of DG Hollow Rotary Actuator

Common structural forms

The motor shaft is concentric with the central axis of the turntable is called direct rotary platform

The motor shaft is parallel to the central axis of the turntable is called side-mounted rotary actuator.

Motor shaft and the center axis of the turntable are in a 90 degree angle is called paraxial type rotating table.

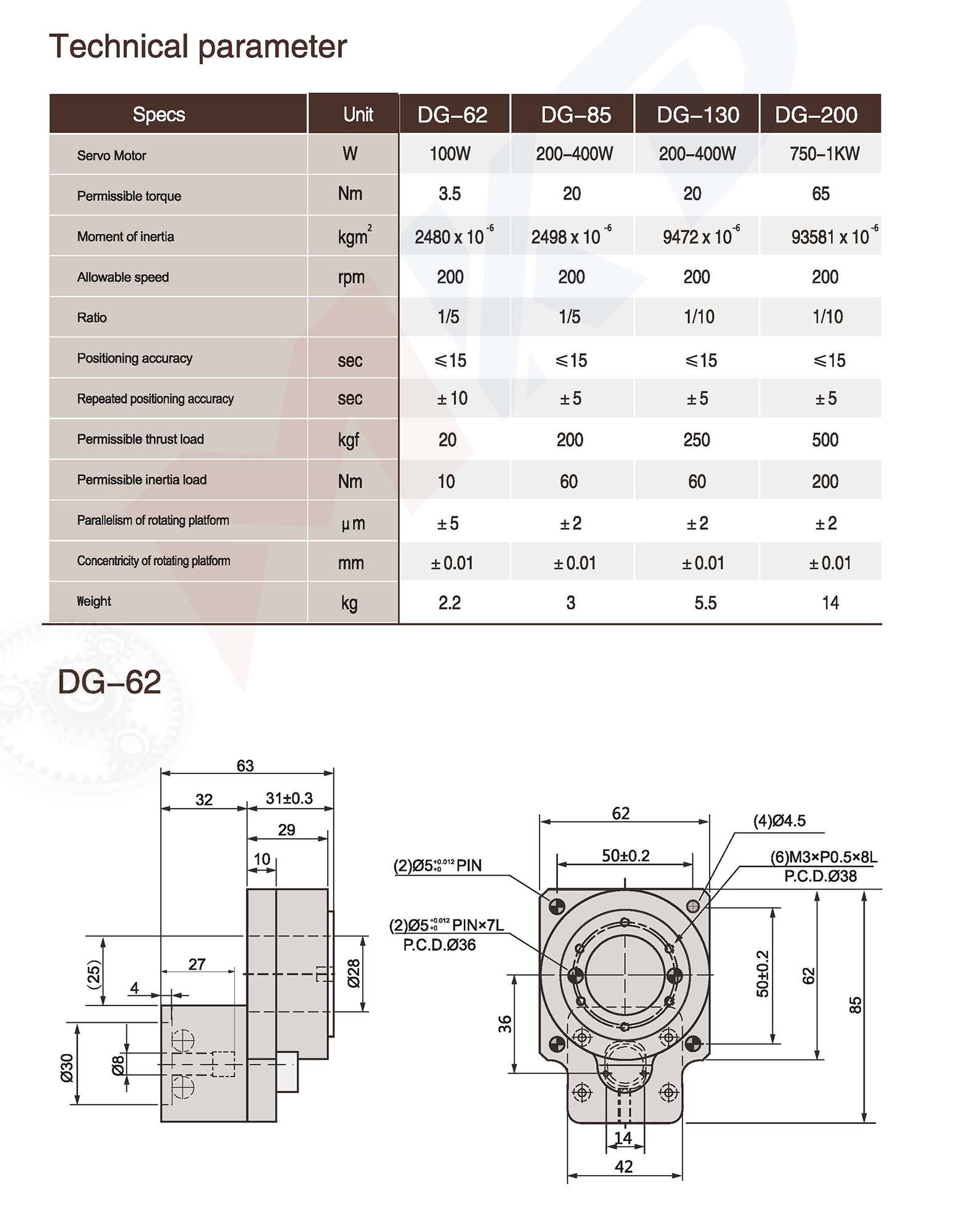

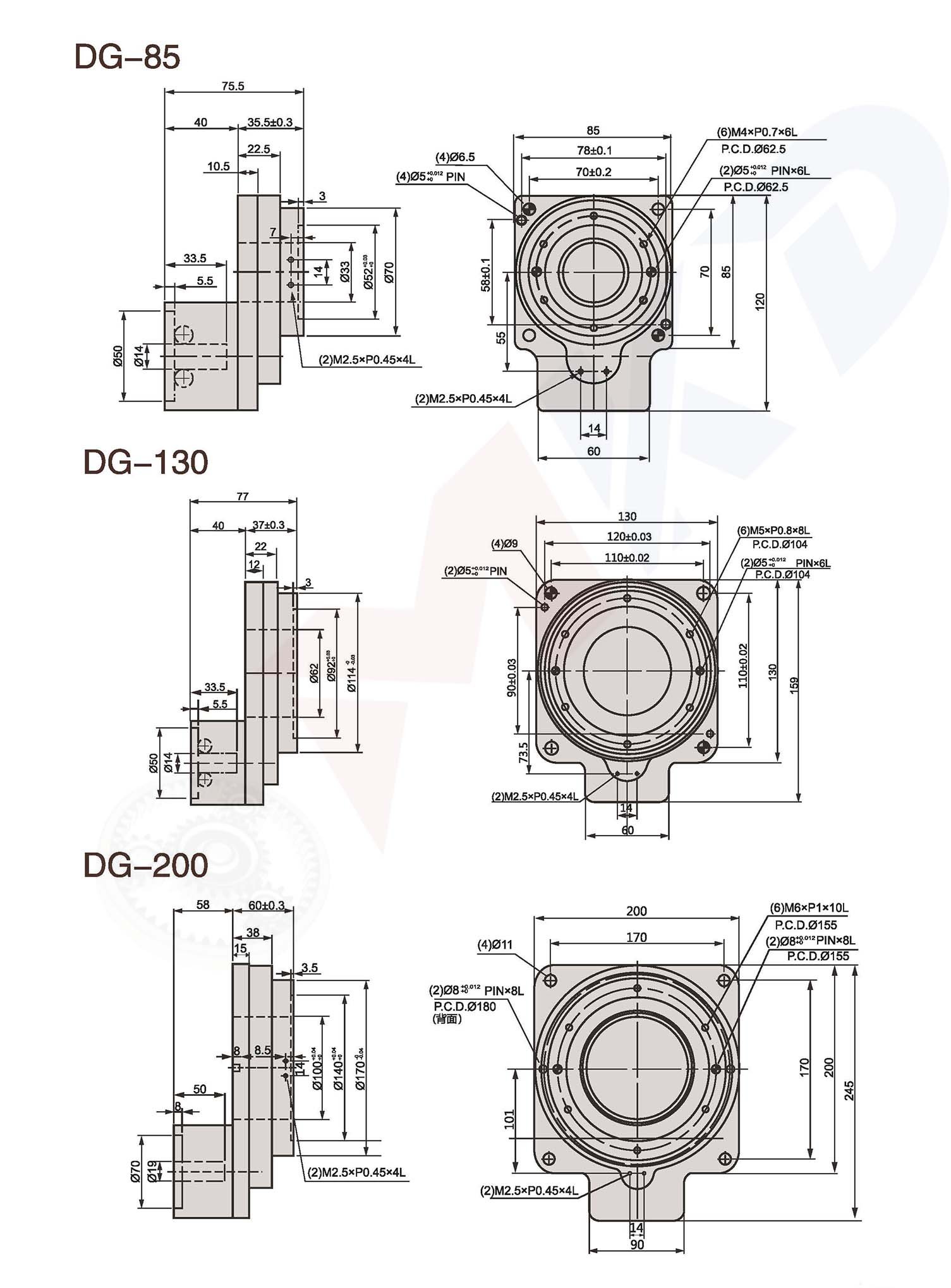

| Specification | Unit | DG-62 | DG-85 | DG-130 | DG-200 |

| Servo Motor | W | 100W | 200-400W | 200-400W | 750-1KW |

| Allowance torque | Nm | 3.5 | 20 | 20 | 65 |

| Moment of Inertia | Kgm² | 2480×10-6 | 2498×10-6 | 9472×10-6 | 93581×10-6 |

| Allowance Speed | rpm | 200 | 200 | 200 | 200 |

| Ratio | 1/5 | 1/5 | 1/10 | 1/10 | |

| Position Accuracy | sec | ≤15 | ≤15 | ≤15 | ≤15 |

| Repeat Accuracy | sec | ±10 | ±5 | ±5 | ±5 |

| Permissible Thrust Load | kgf | 20 | 200 | 250 | 500 |

| Allowance inertial load | Nm | 10 | 60 | 60 | 200 |

| Parallelism of Rotate Plate | um | ±5 | ±2 | ±2 | ±2 |

| Coaxiality of Rotate Plate | mm | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Weight | Kg | 2.2 | 3 | 5.5 | 14 |

It’s time for you to send us an inquiry now to get a 30% discount price. Free technical consult, free technical model selection, free 2d & 3d drawings.

+86 131 6618 0210 (wechat/whatsapp/skype)

Email: gearbox@servogearreducer.com

reducergearbox@gmail.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@servogearreducer.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@servogearreducer.com”.